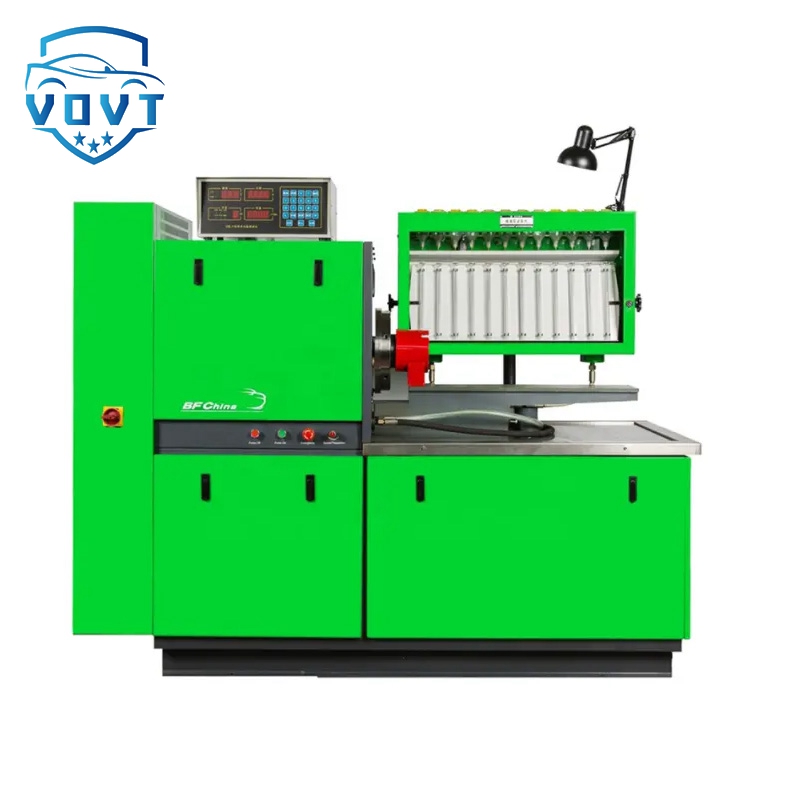

I-ZQYM 318A Ibhentshi Lokuhlola Umshini 12psb Umshini Wokulinganisa Umjovo Wephampu Kadizili

| I-voltage yokuhlinzeka | 220VAC/380VAC |

| Isigaba samandla kagesi | izigaba ezimbili / ezintathu |

| imvamisa | 50HZ/60HZ |

| Okwamanje | 30A(Ubukhulu) |

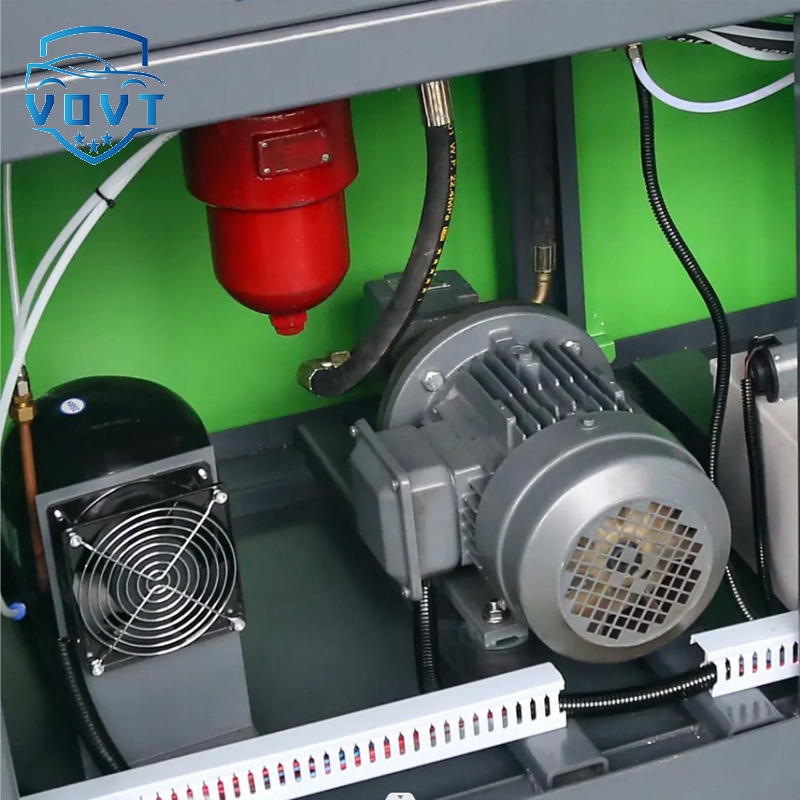

| Amandla emoto | 7.5,11,22kw |

| Ubude bebhentshi lokuhlola ukusuka phansi | 830 mm |

| Izinga lokushisa lokusebenza | ukufudumeza/ ukupholisa umoya ngempoqo |

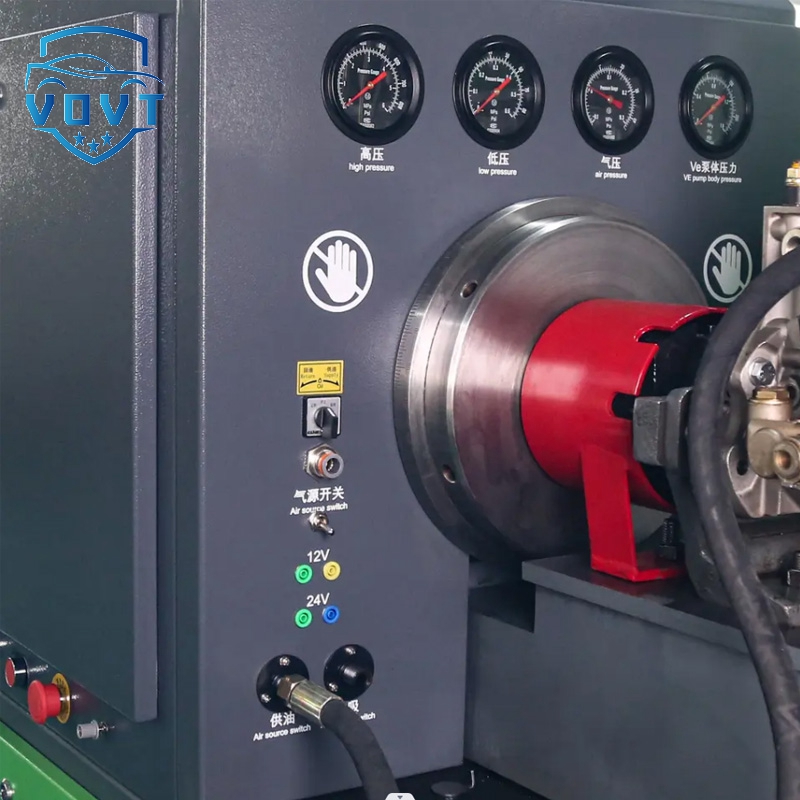

| Ubukhulu bomfutho wesitimela ovamile | 2700 Bar |

| Ukukhuphuka kwengcindezi ye-ECU | 0-200V |

| Izinga lomsindo | <70dB |

| Isisindo | 950kg |

| usayizi | 1800x750x1850mm |

| Usayizi wokupakisha | 2150×750×1850mm |

Izidingo zokusebenza zebhentshi lokuhlola iphampu yomjovo kaphethiloli

Izidingo zokusebenza zebhentshi lokuhlola iphampu yomjovo kaphethiloli

1. Ukufakwa kwephampu yokucindezela okuphezulu ehlolwe ebhentshini lokuhlola

Ipompo yokucindezela okuphezulu igxilwe kumzila wesitimela webhentshi lokusebenzela ngokusebenzisa idivayisi ekhethekile yokubopha.Ingxenye engaphambili yepompo yengcindezi ephezulu ixhumeke ngokuhlanganyela kwendawo yonke yebhentshi lokuhlola ngokusebenzisa ukuhlangana.Lapho ufaka, kufanele kuqinisekiswe ukuthi i-camshaft yepompo ye-high-pressure i-coaxial ne-drive shaft yebhentshi lokuhlola, engafinyelelwa ngokufaka i-pad ekhethekile phakathi kwepompo yokucindezela okuphezulu kanye nesitimela somhlahlandlela.Ngemva kokulungiswa kokuqala, vula ukudayela kwejoyinti yendawo yonke izikhathi ezi-1 kuye kwezingu-2, futhi lapho kuzwakala kushelela, qinisa amabhawodi amakhulu namantongomane ekugcineni.Ngemuva kokufakwa, ipompo yokucindezela okuphezulu kufanele isebenze kahle futhi ngokukhululekile, iqine futhi ithembekile, futhi ingabi nokudlidliza noma ukuxega.

2. Ukuqalisa nokuvala ibhentshi lokuhlola

Xhuma ugesi wezigaba ezintathu ebhentshini lokuhlola, vula isibambo sokulawula isivinini sibe uziro, cindezela inkinobho yokuqalisa imoto (eluhlaza okotshani), bese injini ingaqala.Uma umisa, vula isibambo sokulawula isivinini ukuze unciphise isivinini sokudayela ku-zero, bese ucindezela inkinobho yokumisa (obomvu), ukuze ungami ngesivinini esikhulu, ulimaze ibhentshi lokuhlola futhi ubangele izingozi lapho uqala ngokuzayo.

3. Ukulungiswa kwejubane kwebhentshi lokuhlola

Ngokwejubane elidingekayo nendlela eya ngakhona, khetha igiya lika-gearbox, bese ujika isibambo sokulawula isivinini ukuze ushintshe ijubane.Uma i-engeli evundlile yokuchezuka isibambi sokulawula isivinini ibe nkulu, isivinini siyaphakama.

4. Ukulawulwa kwengcindezi yesistimu kaphethiloli

Ukucindezela ohlelweni lukaphethiloli kulawulwa nge-valve elawula ukucindezela.Ingcindezi ingalungiswa kububanzi obungu-0-0.6 MPa lapho isondo lesandla liphendulwa ngokwewashi, futhi ingcindezi ingalungiswa kububanzi obungu-0-6 MPa lapho iphendulwa ngokuphambene newashi.Uwoyela ocindezelayo uthunyelwa usuka endaweni yokuphakelwa kukawoyela yebhentshi lokuhlola ukuya empompini yokucindezela okukhulu ngaphansi kokuhlolwa ngepayipi likawoyela.

5. Ukulawula izinga lokushisa kwamafutha

Uma izinga lokushisa likaphethiloli lingaphansi kuka-40°C, vula isibambo sevalvu yokushisisa siye newashi ukuze ukhuphule izinga lokushisa likaphethiloli.Lapho izinga lokushisa likaphethiloli lifinyelela ku-40°C, vala ngokushesha i-valve yokushisisa ukuze umise ukushisa.

3 Ukugcinwa nokunakekelwa kwebhentshi lokuhlola

(1) Ukuze uqinisekise ukunemba kokuhlolwa kwebhentshi lokuhlola, hlola ukucindezelwa kokuvula komjovo ojwayelekile wamafutha njalo, okufanele ube ngu-17.5 MPa;hlola njalo ukufana komjovo ojwayelekile wamafutha, uma kukhona umehluko, lungisa ingcindezi yokuvula ukuze ulungise Linganisa, uma kungenzeki, buyisela umjovo ojwayelekile.

(2) Uphethiloli osetshenziswe lapho kuhlolwa kufanele kube uwoyela wedizili omncane osenemvula ngaphezu kwamahora angama-48.Lapho kulungiswa amaphampu angu-500 omjovo kaphethiloli noma ngemva kwamahora angu-400 okusebenza, kufanele kushintshwe uwoyela omusha.Lapho ushintsha uwoyela, hlanza ithangi likaphethiloli bese uhlunga ngophalafini.30# noma 46# uwoyela we-steam turbine kufanele wengezwe ku-gearbox kanye nokudluliswa kwe-hydraulic okuguquguqukayo okuqhubekayo.Jova uwoyela oyimishini ongu-40# noma u-150# uwoyela oyimishini ku-gearbox, izinga likawoyela akumele libe ngaphansi kunendololwane yokugcwalisa uwoyela, bese uyishintsha njalo emahoreni angama-400 noma uhhafu wonyaka.Ama-bearings asesihlalweni se-tachometer adinga ukugcotshwa njalo ngamafutha omshini noma uwoyela we-turbine.Lapho ufaka uphethiloli, susa iwashi eliwumshini bese ujova uwoyela wokugcoba embotsheni yesihlalo se-tachometer.

(3) Ngaphambi kokuqala, kungcono ukusebenzisa i-lever ukuzungezisa ukudayela kuze kube yilapho injini kanye nepompo yokuphakela uphethiloli kuzungeza ngesikhathi esisodwa, bese uqala ukusebenza.

(4) Ungawashiyizi amagiya noma uqale ibhentshi lokuhlola ngesivinini esikhulu ngesikhathi sokusebenza kwebhentshi lokuhlola, ngaphandle kwalokho ukuhanjiswa okuguquguqukayo okuqhutshwa kwamanzi okuqhutshwa kwamanzi kuzolimala.Uma usebenzisa isibambo sokulawula isivinini, isivinini kufanele sinyuswe noma sehliswe kancane kancane futhi kancane, futhi isivinini akufanele sisetshenziswe ngokushesha.Lapho uvala, ijubane kufanele lilungiswe ku-zero, ukuze lingalimazi uhlelo lokudlulisela futhi lithinte impilo yesevisi.